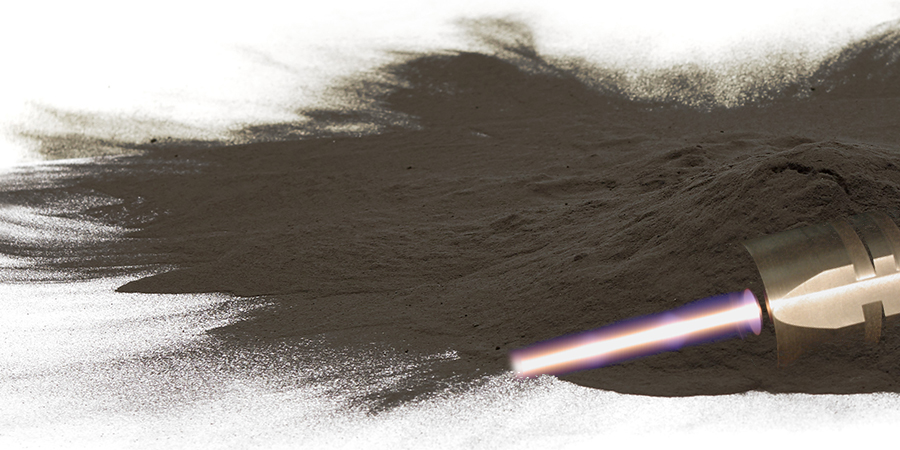

The Mechanofuse® series includes Nickel-based (SFN) and Iron-based (SF6) powders, specifically developed for thermal spray and fuse applications. Produced via a proprietary mechano-chemical process, these powders form fully dense, metallurgically bonded coatings reinforced with hard ceramic phases, offering excellent wear, abrasion, and corrosion resistance.

SFN delivers high-thickness coatings (up to 2 mm), with a composite microstructure of ceramics (1600 HV) and a tough Ni matrix (600 HV), achieving 58–63 HRC hardness.

SF6, a cost-effective and sustainable Fe-based alternative, offers higher hardness (66–70 HRC) and improved toughness.

Applications include hydraulic cylinders, rotors, valves, sleeves, and high-load sliding components.

Suitable for combustion flame, HVOF/HVAF, and plasma spray, with fusing via torch, controlled atmosphere furnace, or induction. Mechanofuse® coatings are ideal for extending the life of industrial components operating in severe mechanical and chemical environments.

| Iron | Cromium | Nichel | Boron | Silicon | Carbon | Others |

|---|---|---|---|---|---|---|

| Bal | 14.0 wt% | 6.0 wt% | 3.5 wt% | 2.5 %wt | 1.0%wt | <1.0%wt |

| Powder size | Skeletal density | Coating Hardness: | Fusing Temperature |

|---|---|---|---|

| μm -53+10 | g/cm³ 7.09 | >1000 HV | 1100°C |