WCrY

Refractory Alloy for Nuclear Fusion Applications

WCrY is an advanced tungsten-based refractory alloy engineered for Hot Isostatic Pressing (HIP) consolidation, followed by high-temperature annealing above 1500 °C to eliminate Cr-rich secondary phases and stabilize a single-phase bcc structure. This thermal treatment process is essential for achieving thermal shock resistance and mechanical integrity under extreme operational conditions.

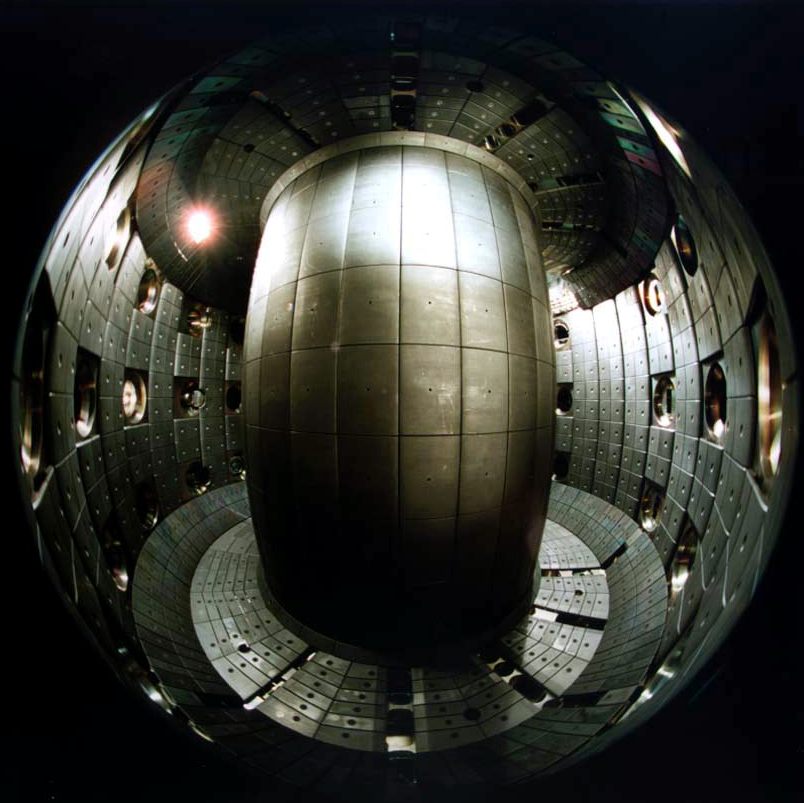

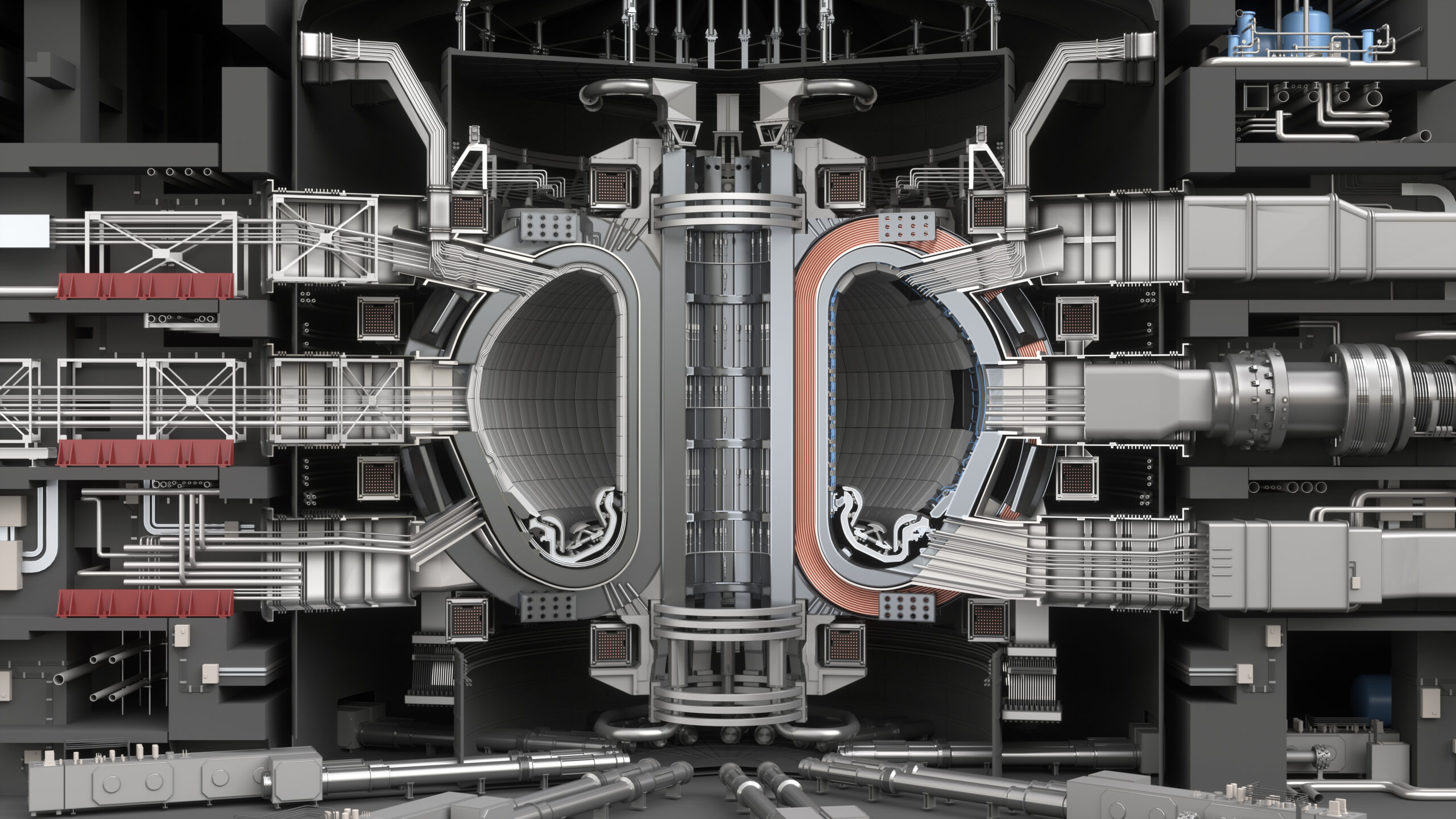

Designed to withstand steady-state and transient heat loads in the MW/m² range, WCrY alloy is ideal for plasma-facing components such as divertor and first wall assemblies in fusion reactor environments. The strategic addition of chromium and yttrium enhances high-temperature oxidation resistance up to 1000 °C and promotes grain refinement through in-situ oxide dispersion strengthening (ODS).

With its exceptional combination of thermal stability, radiation resistance, oxidation protection, and mechanical performance at elevated temperatures, WCrY represents a leading material solution for next-generation fusion energy systems and other extreme environment applications.

COMPOSITION

Tungsten bal. – Chromium 11-13% – Yttrium 0.5%

Refractory Alloy for Nuclear Fusion Applications