High Entropy Hardmetals

Next-Generation Wear-Resistant Composites

As part of the EU-funded CoBRAIN project,

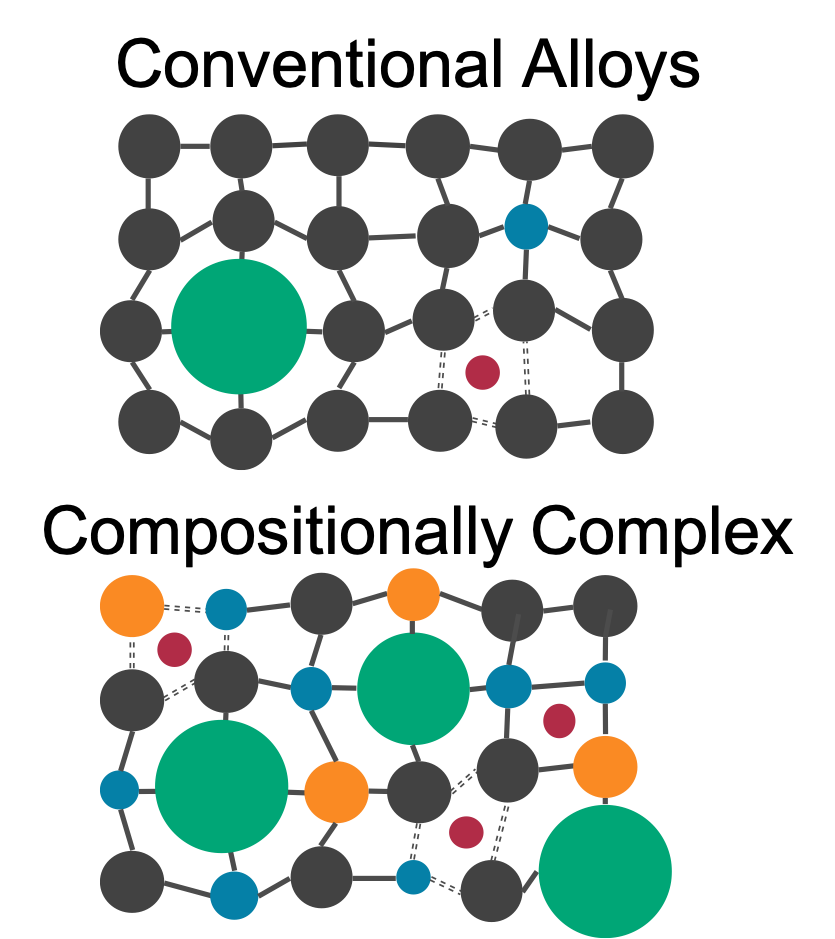

MBN has developed an innovative class of High Entropy Hardmetals (HHMs), combining 60 vol% Titanium Carbide (TiC) reinforcement with customizable High Entropy Alloy (HEA) matrix compositions. The TiC carbide phase is synthesized in-situ via mechanochemical processing, ensuring uniform dispersion of submicron carbide particles throughout the multi-principal element alloy matrix—critical for achieving superior hardness, wear resistance, and thermal stability.

These advanced cermet powders are engineered specifically for thermal spray coating applications including HVOF (High Velocity Oxygen Fuel), HVAF (High Velocity Air Fuel), and Cold spray deposition, where they form dense, adherent wear-resistant coatings with exceptional abrasion resistance, corrosion protection, and high-temperature oxidation resistance. Produced via MBN’s proprietary Mechanomade® high-energy ball milling technology, the powders feature controlled particle size distribution and optimised phase distribution for consistent sprayability, deposition efficiency, and coating performance.

COMPOSITION

Titanium carbide 60% – Metallic matrix 40%

Matrix options: AISI 316L, AISI 410, AISI 940, FeCr, NiCr, AlCuCrFeNi, CrFeMnNiSi

Next-Generation Wear-Resistant Composites