Magnesium-Based Alloys for Solid-State Hydrogen Storage Systems

MBN has developed advanced magnesium-based metal hydride alloys and nanostructured hydrogen storage composites using its proprietary Mechanomade® high-energy ball milling process, successfully overcoming the significant processing challenges associated with highly reactive and ductile magnesium.

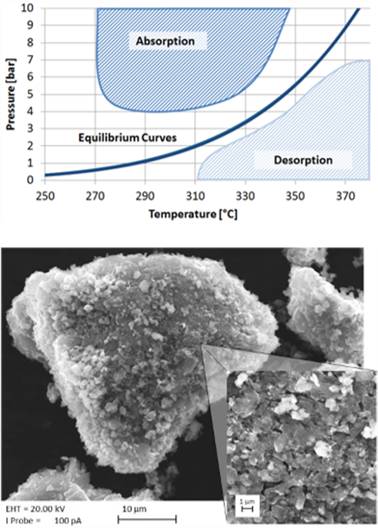

Mg-based hydrogen storage materials are synthesized directly in powder form with refined nanocrystalline grain structure (grain size <100 nm) that dramatically accelerates hydrogen diffusion kinetics along grain boundary networks. Nano-scale catalytic additives (Nb₂O₅, TiO₂, V₂O₅) are homogeneously dispersed during the milling process, promoting efficient dissociation of H₂ molecule into atomic hydrogen at the powder surface—the rate-limiting step in hydrogen absorption.

This catalytic enhancement strategy significantly improves:

Gravimetric hydrogen storage capacity (up to 7 wt% H₂)

Hydrogen absorption/desorption kinetics (fast cycling rates)

Operating temperature reduction (150-300 °C vs. 350+ °C for pure Mg)

Activation time minimization (first hydrogenation cycle)

Cycle life stability (reversible hydrogen uptake/release)

MBN’s magnesium enables safer solid-state hydrogen storage, lightweight tank systems, and more efficient energy density compared to compressed or liquefied hydrogen, supporting next-generation clean energy infrastructure, hydrogen fuel cell vehicles, renewable energy storage, and accelerating the adoption of hydrogen as a sustainable energy carrier for decarbonization.

COMPOSITION

Mg, Mg-Ni, Mg-Fe, Mg-Ti alloy systems

PROPERTIES

Hydrogen capacity 5-7 wt% (reversible)

Operating pressure 1-10 bar H₂

Operating temperature 150-300 °C

Absorption kinetics <5 min for 80% capacity (optimized formulations)

Desorption kinetics <10 min at 250 °C

Cycle life >1000 absorption/desorption cycles

Particle size 10-100 µm (application-specific)

Catalyst loading 1-5 wt% transition metal oxides

Development Services: Custom alloy composition design, kinetics optimization, catalyst screening, cycling stability testing, tank integration support.

MBN has developed advanced magnesium-based metal hydride alloys and nanostructured hydrogen storage composites using its proprietary Mechanomade® high-energy ball milling process, successfully overcoming the significant processing challenges associated with highly reactive and ductile magnesium.