Nanocomposite Masterbatch

Additives for Enhanced Gas Barrier Packaging Films

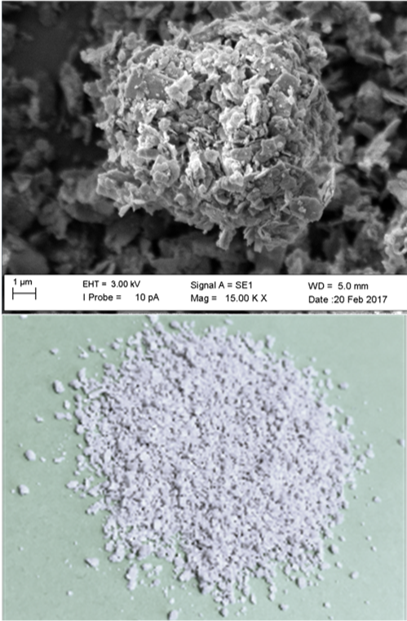

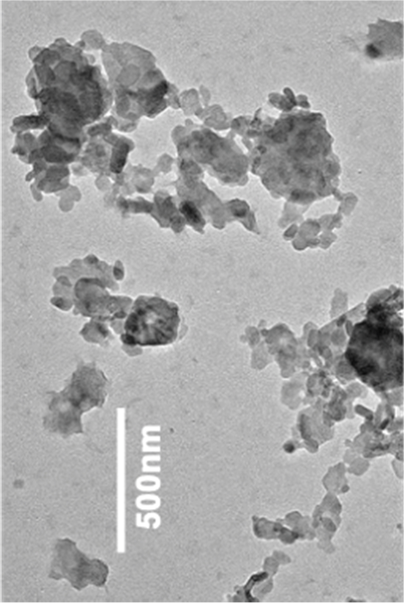

MBN offers nanocomposite masterbatch additives engineered to enhance gas barrier properties in polymer packaging films. Produced via Mechanomade® mechanochemical processing, these pre-dispersed nanoparticle masterbatches include graphene, nanoclays, and silica in dust-free, easy-to-handle pellets for industrial polymer compounding.

Advanced Processing Technology:

Mechanical alloying actively predisperses and exfoliates nanoparticles, increasing surface reactivity and ensuring uniform distribution within the polymer matrix—significantly simplifying compounding processes vs. direct nanoparticle addition.

Performance & Applications:

Demonstrates up to 50% improvement in gas barrier performance when integrated into PP (polypropylene), HDPE (high-density polyethylene), PLA (polylactic acid), or PHB (polyhydroxybutyrate). Ideal for multilayer packaging films, food packaging, and biodegradable packaging requiring extended shelf life and improved material efficiency.

Compatibility: Both polar and non-polar polymers. Provides safe, scalable advanced packaging solutions.

COMPOSITION

Polymer masterbatch with graphene / Nanoclays / Silica

PROPERTIES

Min. Solid content 80 wt.%

Granule size <2 mm

Colour Pale yellow

Additives for Enhanced Gas Barrier Packaging Films