Our materials are engineered to enhance the performance of diamond tools while reducing manufacturing costs by optimizing sintering processes.

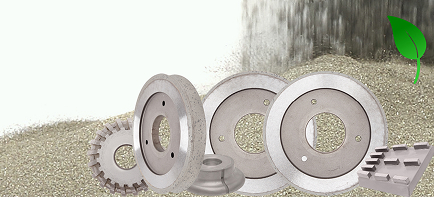

We make green material solutions as alternatives to cobalt-based alloys, suitable for a wide range of applications, including natural stone, agglomerate, ceramic, concrete, and glass processing.

The Eco-Friendly Iron based metal bond for ceramic application

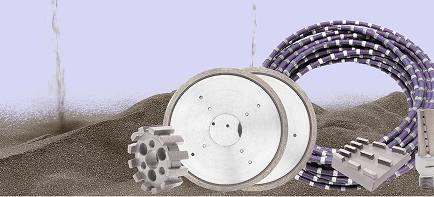

Multipurpose metal bond for free sintering and self brazing application

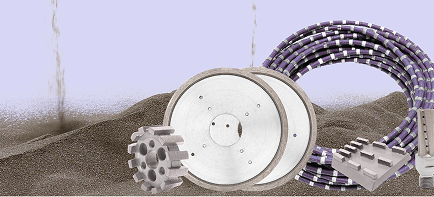

The laser weldable powders adaptable for your application