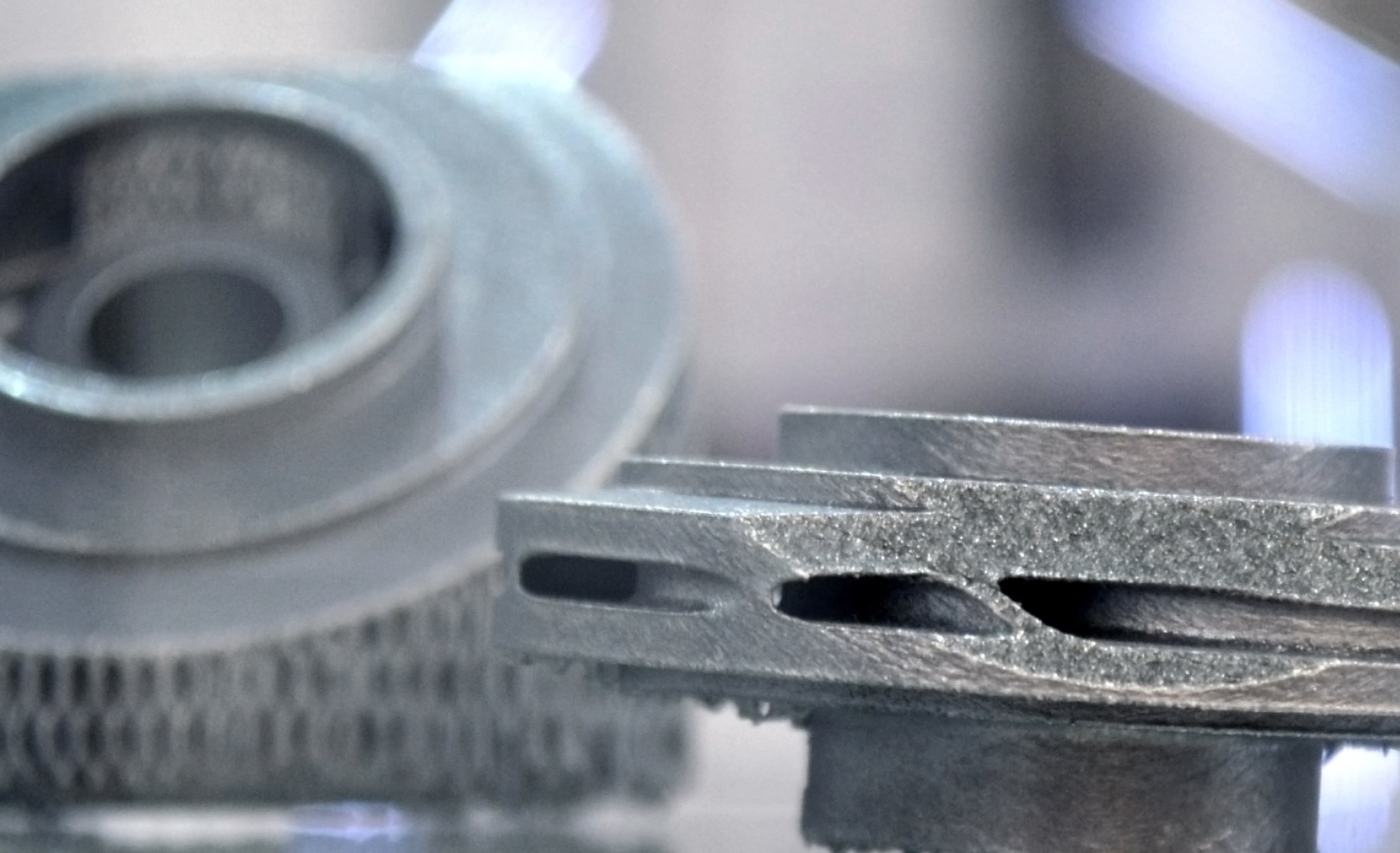

MBN Nanomaterialia

Nanostructured Powder manufacturing division

Production of nanostructured metal and composite powders. Powders are produced by a proprietary High Energy Ball Milling technology.

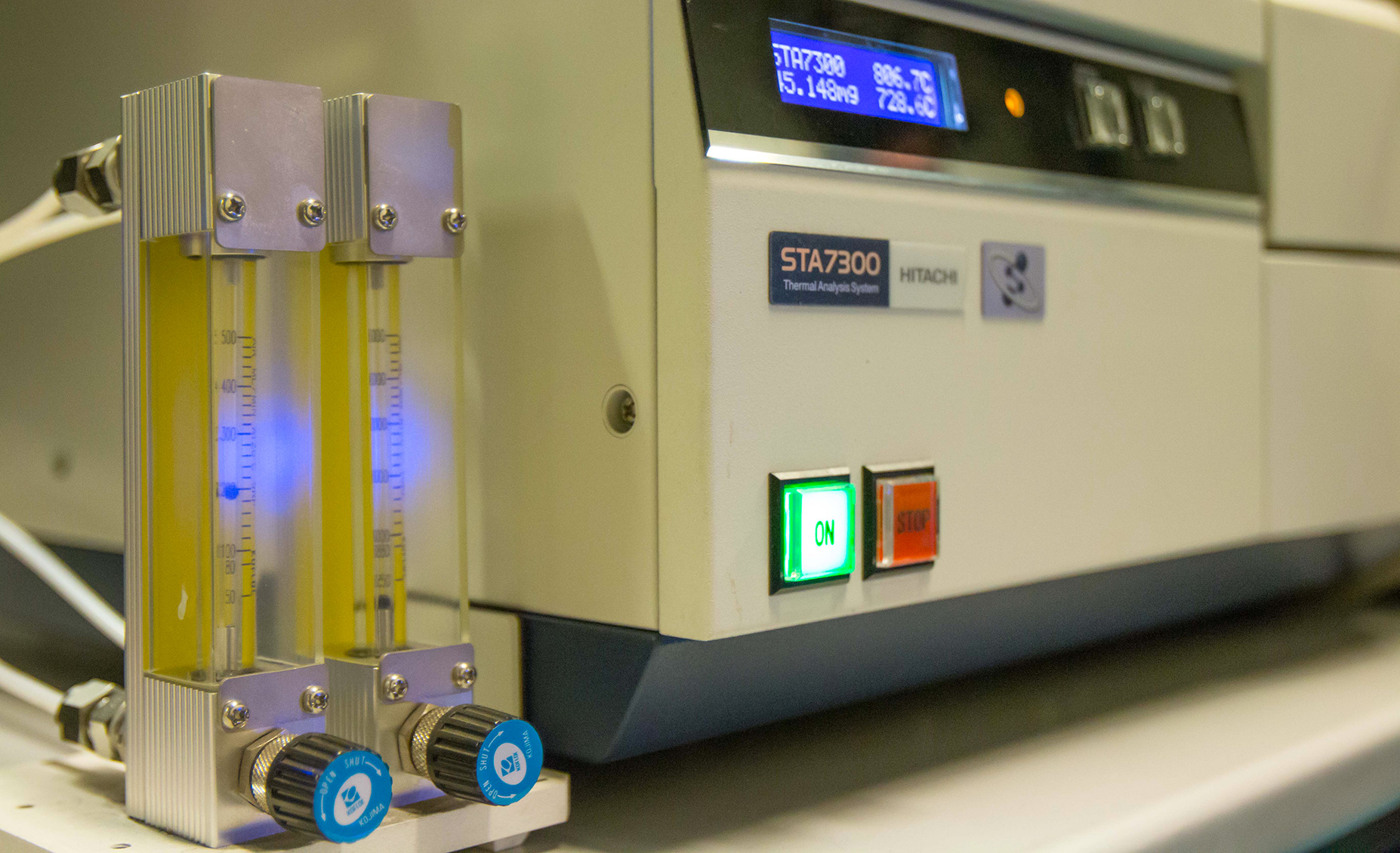

Matres Scrl

Material engineering division

Material design and project coordination of research activities for the innovation on advanced materials and processes.

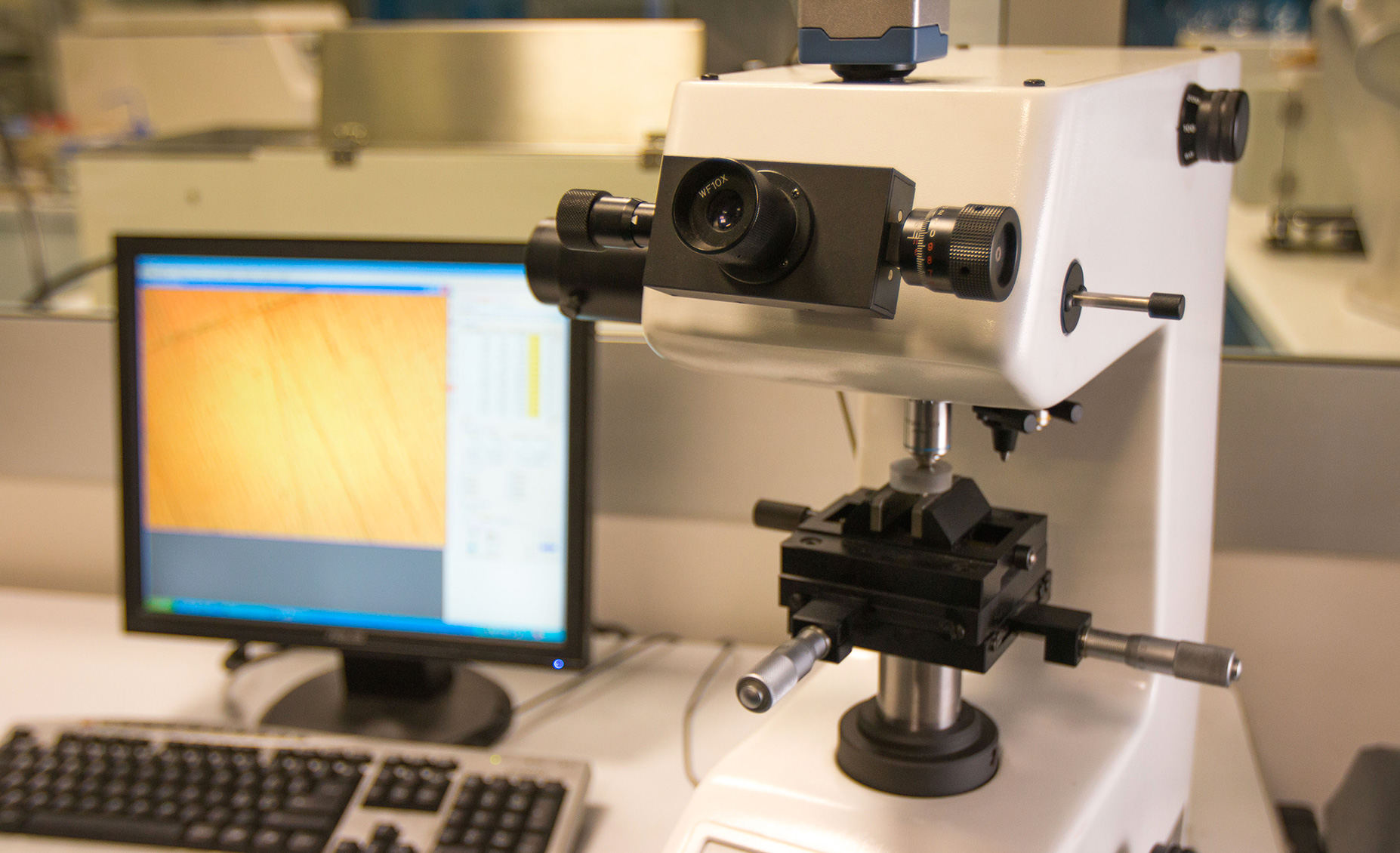

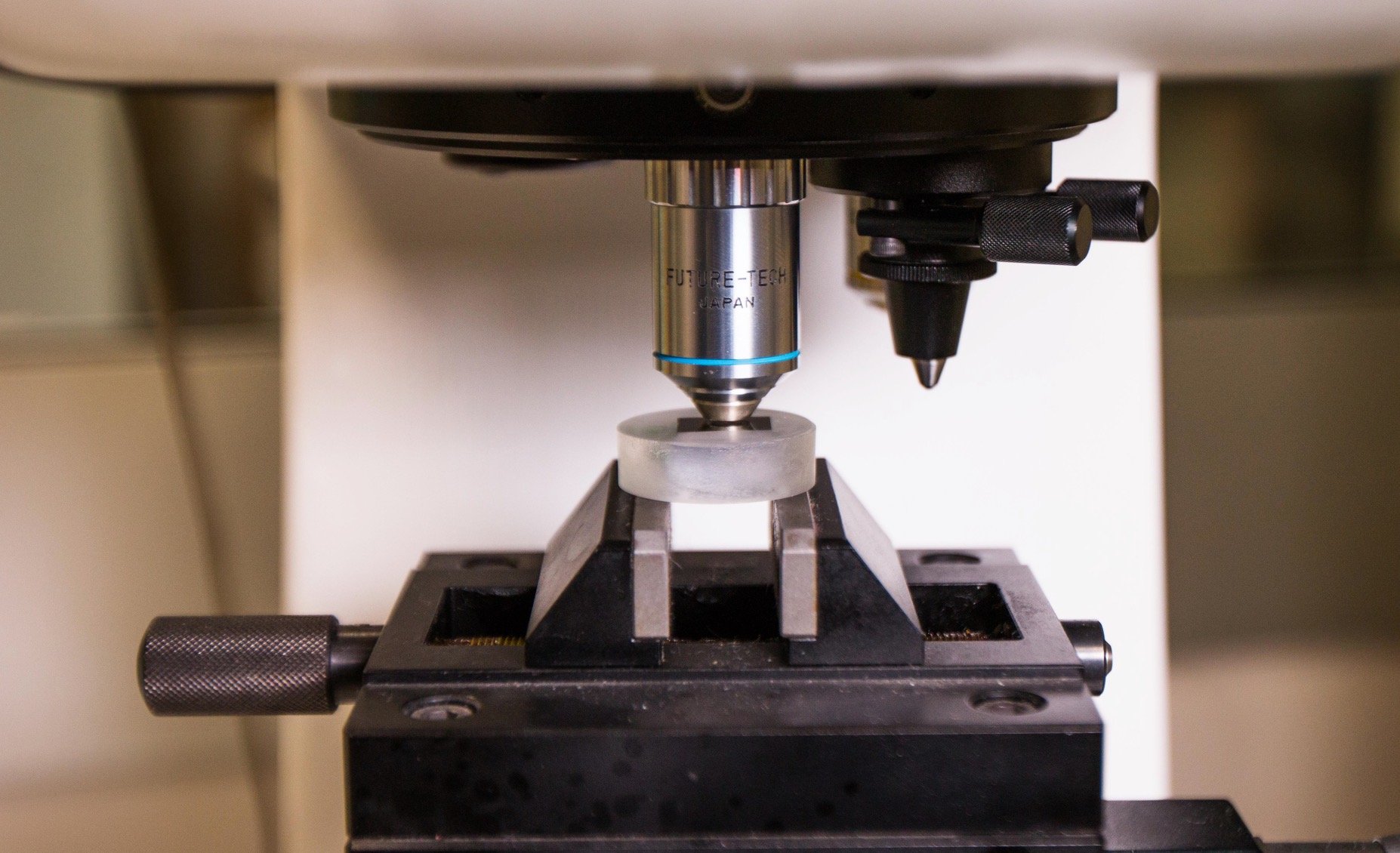

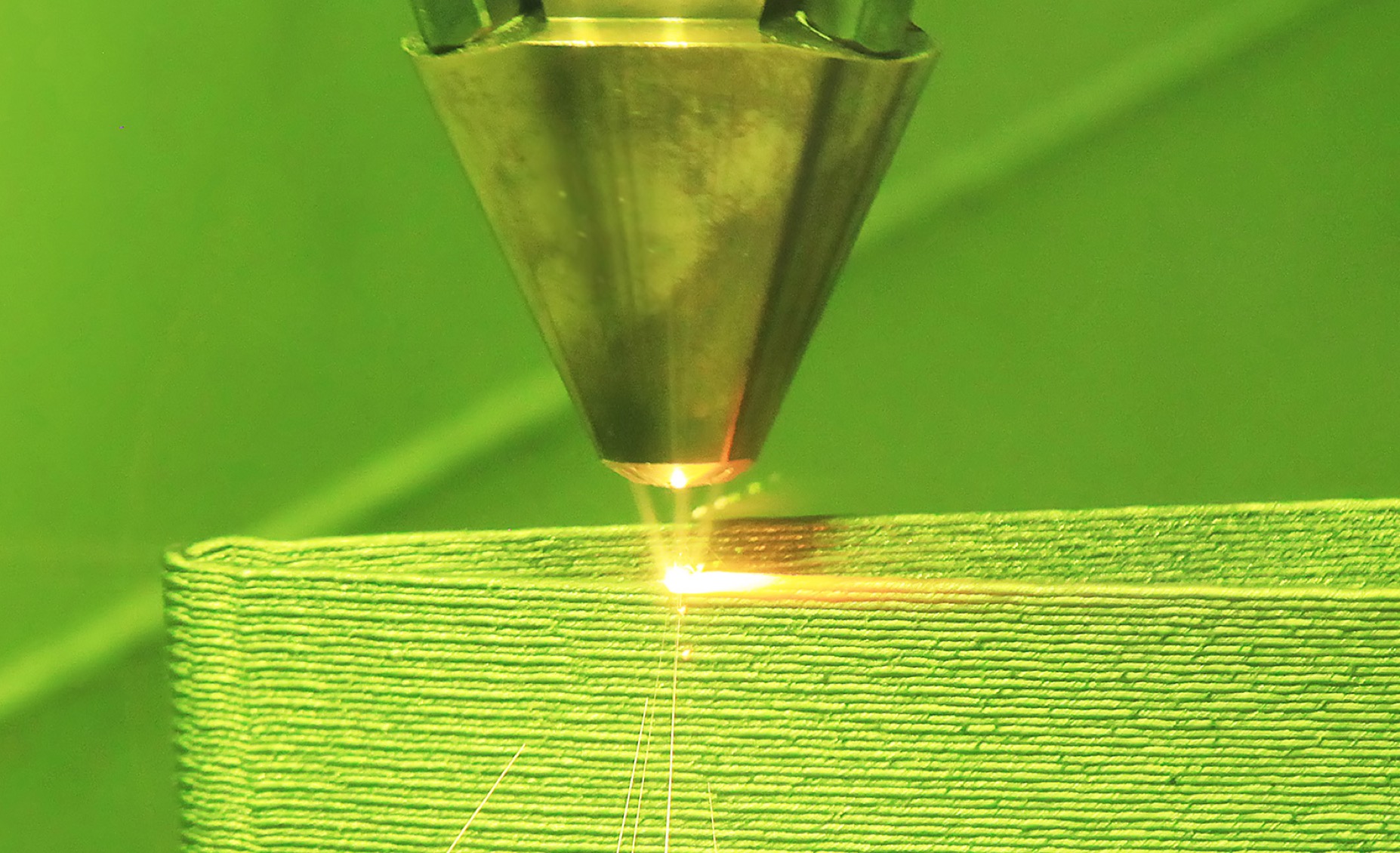

Manudirect Srl

3D Micro-manufacturing division

Additive manufacturing platform technology for the realization of high precision 3D- micro objects.