GREEN Nanostructured CerMets – Sustainable Coating Powders for Extreme Wear and Tribological Demands

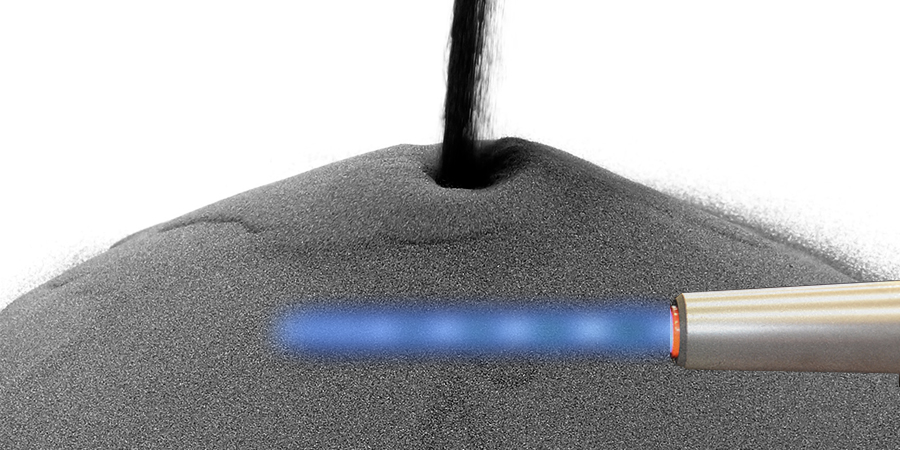

MBN Nanomaterialia introduces a new class of GREEN Nanostructured CerMets, engineered for advanced tribological coatings and mechanical protection in demanding applications. These innovative powders combine hard ceramic phases such as TiC with environmentally friendly metallic binders like Ti and FeCr, offering high performance with reduced ecological impact.

Unlike traditional WC-Co materials, MBN’s Co-free CerMets eliminate reliance on critical raw materials while maintaining—or even improving—key functional properties such as hardness, wear resistance, and oxidation stability. Formulations such as TiC-NiCr, TiC-FeCr, and WC-Ti are designed to deliver excellent abrasion resistance and thermal stability, making them ideal for thermal spray coatings in automotive, energy, and tooling sectors.

Developed using MBN’s proprietary Mechanomade® process, the powders feature a nanostructured matrix that resists decarburization during spraying and ensures superior mechanical bonding. Their low density also contributes to lighter components, supporting energy efficiency and sustainable design.

Key Benefits:

◉ Cobalt-free and low-density alternatives

◉ Nanostructured for enhanced wear and toughness

◉ Decarburization-resistant during spraying

◉ Suitable for HVOF and plasma spray applications

◉ Ideal for eco-conscious high-performance coatings

MBN’s GREEN CerMets represent the next step in sustainable surface engineering—where performance, safety, and environmental responsibility go hand in hand.

| product name | NbC FeCr | NbC NiCr | TiC-FeCr | TiC-NiCr | Ti-WC |

|---|---|---|---|---|---|

| Elements composition | NbC60-FeCr 40 | NbC60-NiCr 40 | TiC75-FeCr25 | TiC60-FeCr40 | WC77-23Ti |

| Density (g/cm³) | 7.5 | 8.0 | 5.4 | 6.2 | 9.4 |

| Hardness HV scale (HV) | 1100 | 1050 | 1200 | 1000 | >1000 |

| Wear Rate (mm³/Nm) | 1x10-6 | 2x10-7 | 2x10-6 | 5x10-7 | nd |