Aluminium Alloys

With MBN’s proprietary MechanoMade® powders, various light alloys are available Nanostructured Aluminum Metal Matrix Composites reinforced with Al₂O₃-Al₄C₃ phases, achieving YTS of 560 MPa

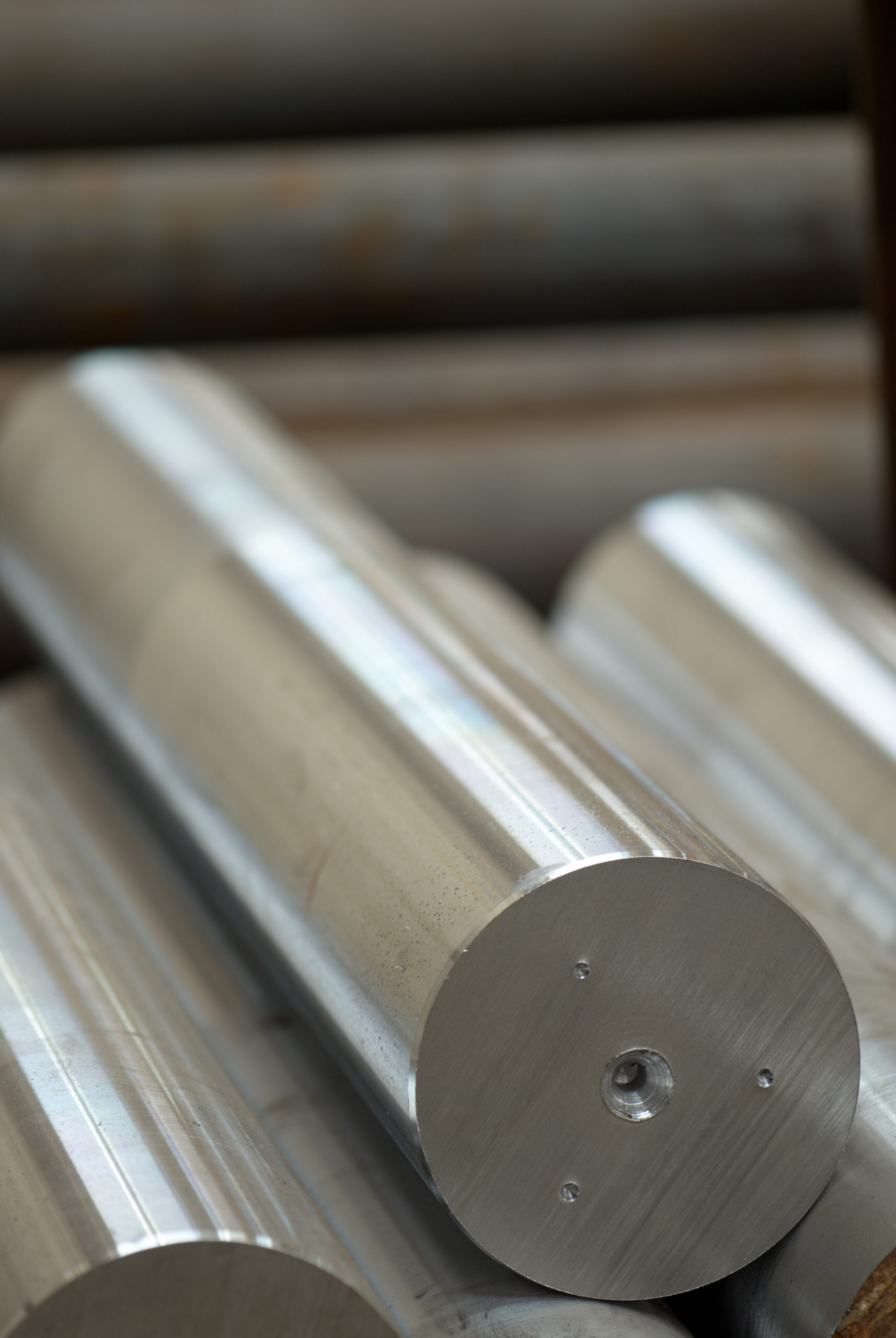

MBN offers a complete end-to-end prototyping pathway for Al-based alloys and composites, starting from mechanical alloying to fully formed semi-finished components. Materials options include Aluminum matrix composites (Al-MMCs) reinforced with SiC for wear resistance, B₄C for lightweight armour and neutron absorption or AlN for thermal conductivity and stability

The Prototyping Process includes Powder Production- Nanostructured powders synthesised by mechanical alloying (Mechanomade®) and Forming Options such as hot isostatic Pressing, followed by extrusion, or direct extrusion of pre-heated green compacts

This integrated approach enables rapid development of advanced lightweight materials tailored for aerospace, defence, and automotive applications.

With MBN’s proprietary MechanoMade® powders, various light alloys are available Nanostructured Aluminum Metal Matrix Composites reinforced with Al₂O₃-Al₄C₃ phases, achieving YTS of 560 MPa