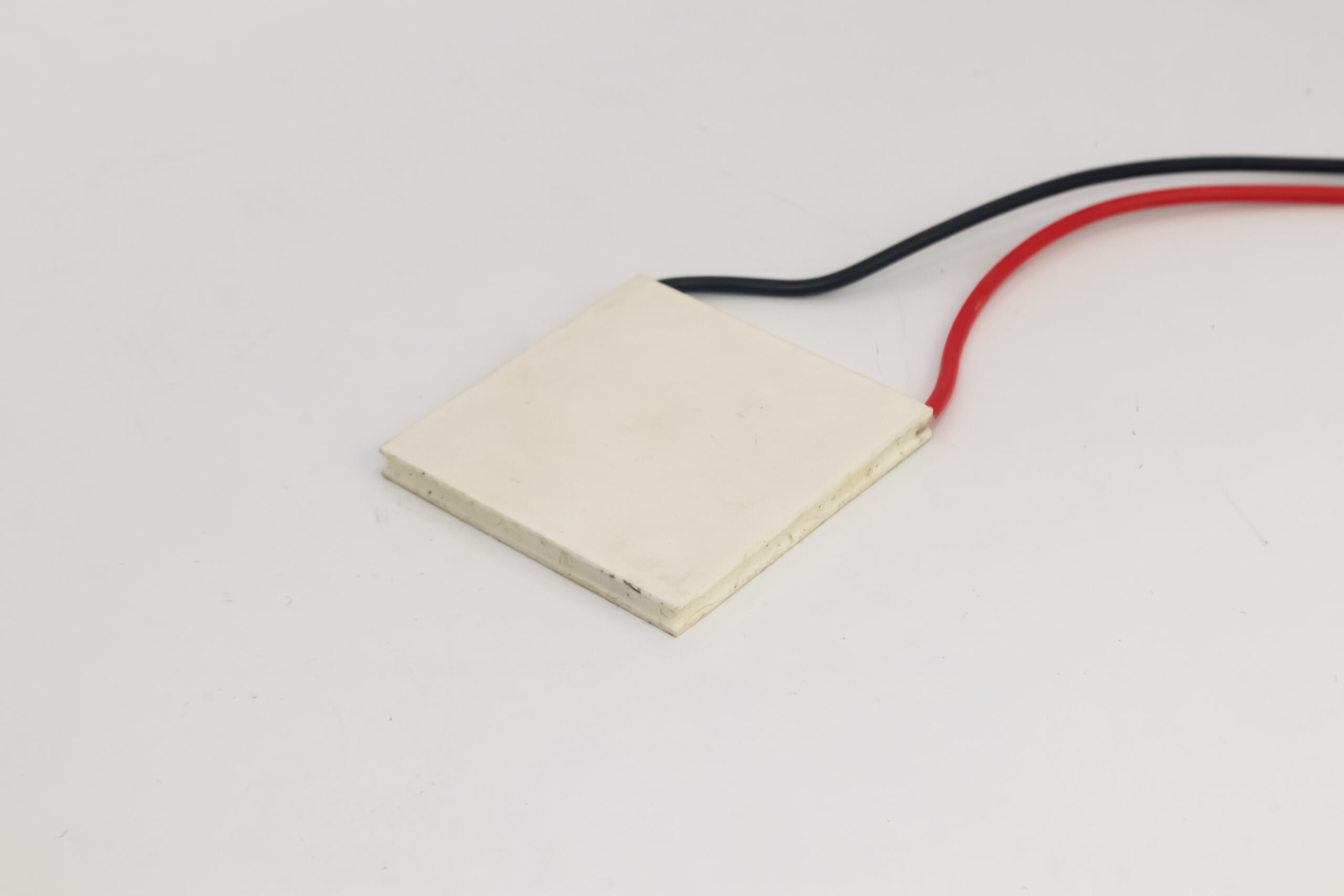

P-type Tetrahedrite

Thermoelectric materials from mineral waste

Within the START project, developed an advanced p-type thermoelectric powder based on the tetrahedrite compound Cu₁₂₋ₓ(TM)ₓSb₄S₁₃ (TM = Fe, Zn). Tetrahedrites are copper-based sulfide minerals valued for their low thermal conductivity, use of earth-abundant and non-toxic elements, and strong potential in sustainable energy conversion. Through dual substitution of Cu with Fe and Zn, MBN’s material achieves optimised carrier concentration, delivering a thermoelectric figure of merit (ZT) > 1 with peak efficiency near 350 °C.

Produced via the proprietary Mechanomade® process, this zero-waste solid-state synthesis ensures homogeneous phases and precise control over composition. Consolidation by Spark Plasma Sintering (SPS) yields dense, fine-grained legs with high electrical conductivity, low thermal conductivity, and robust mechanical integrity.

COMPOSITION

Copper bal. – Antimony 30% – Sulphur 25% – Zinc 2% – Iron 1.7%

PROPERTIES

Seebeck coefficient 240–250 μV/K

Electrical resistivity 55–60 μΩ·m

Thermal conductivity 0.6 W/mK

ZT 1.1

Power factor 1 mW/mK²

Thermoelectric materials from mineral waste